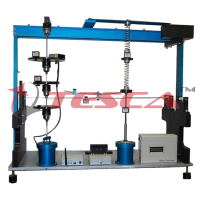

Bearing Maintenance Trainer

Order Code: 32131

Category: Strength of Materials Lab

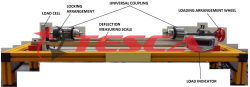

Features: Steel base plate, 30" long, allowing for convenient mounting across the width of a standard shop bench. 4 Steel shaft mounting brackets which, when used in combination, allow for mounting of shafts in di...

SPECIFICATION

Features:

- Steel base plate, 30" long, allowing for convenient mounting across the width of a standard shop bench.

- 4 Steel shaft mounting brackets which, when used in combination, allow for mounting of shafts in different orientations.

- 4 High-grade alloy steel CNC-machined stub shafts allowing for installation of all bearings.

- Provision for installation of radial ball bearings and cylindrical roller bearings with loose and interference fit applications.

- Provision for installation of spherical roller bearings on a tapered shaft, adapter sleeve, and withdrawal sleeve.

- (Includes two different internal clearance calculations.)

- Provision for installation of a radial ball bearing in an externally seated application.

- Provision for bearing removal using a gear puller on a back-up gear.

- 8 Bearing types provided.

- Shaft seal application.

- High-durability urethane coatings throughout.

- Overall size of 750L x 300W x 300H in mm & weight 45Kgs

Tesca Bearing Maintenance Trainer is a realistic, heavy-duty device that allows for convenient and consistent training in the identification, installation, and removal of a variety of industrial-quality rolling element bearings.

The basic device provides for two student workstations. Using two of four CNC-machined stub shafts provided, in combination with shaft mounting brackets, training can take place at both ends of the device.

A selection of large diameter spherical roller bearings, radial ball bearings, angular contact bearings, cylindrical roller bearings, a needle bearing, and shaft seals are provided. Additionally, "loose" and "interference" fit bearing seating locations are provided.

An extended version adds a 24" long, multi-land shaft and with two pillow blocks, This allows an even greater variety of configurations and fits, in addition to allowing for exercises using an arbor press and the locating of a shaft within pillow blocks.

This device, together with a variety of hands-on exercises, creates a complete performance-based course in the maintenance of industrial bearings.

Technical Specification:

Four (4) units of steel shaft mounting brackets per trainer, allowing shafts to be mounted in different orientations.

Four (4) units machined steel shafts per trainer allowing for installation of all bearings.

The trainer has provisions for the installation and removal of 7 different bearings consisting:

a. Radial ball bearing

b. Cylindrical ball bearing.

c. Spherical roller bearing.

d. Angular contact bearing

e. Needle bearing.

The trainer has provisions for the installation and removal of different bearings:

a. loose fit

b. interference fit

c. tapered shaft

d. adapter sleeve

e. externally seated.~

Overall size of 750L x 300W x 300H in mm & weight 45Kgs

91-9829132777

91-9829132777